01

Solid state research

Crystal structure prediction empowering solid-state chemistry solutions

02

overview

AI-powered platform

enhancing solid-state R&D

XtalPi combines computational chemistry and AI to empower pharmaceutical solid-state research with advanced resources and expert support.

Application

Advanced solid state computational service

Platform

Crystal structure prediction

Evaluate the polymorphic risk of the target system

Virtual Screening

Select optimal coformers/solvents for crystallization

Morphology prediction

Predict morphology under solvents/additives conditions

Underlying Technology

Cloud computing platform

High throughput automation lab center

Data engineering center

Theoretical basis

Quantum physics

AI & Machine learning

03

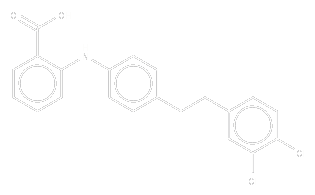

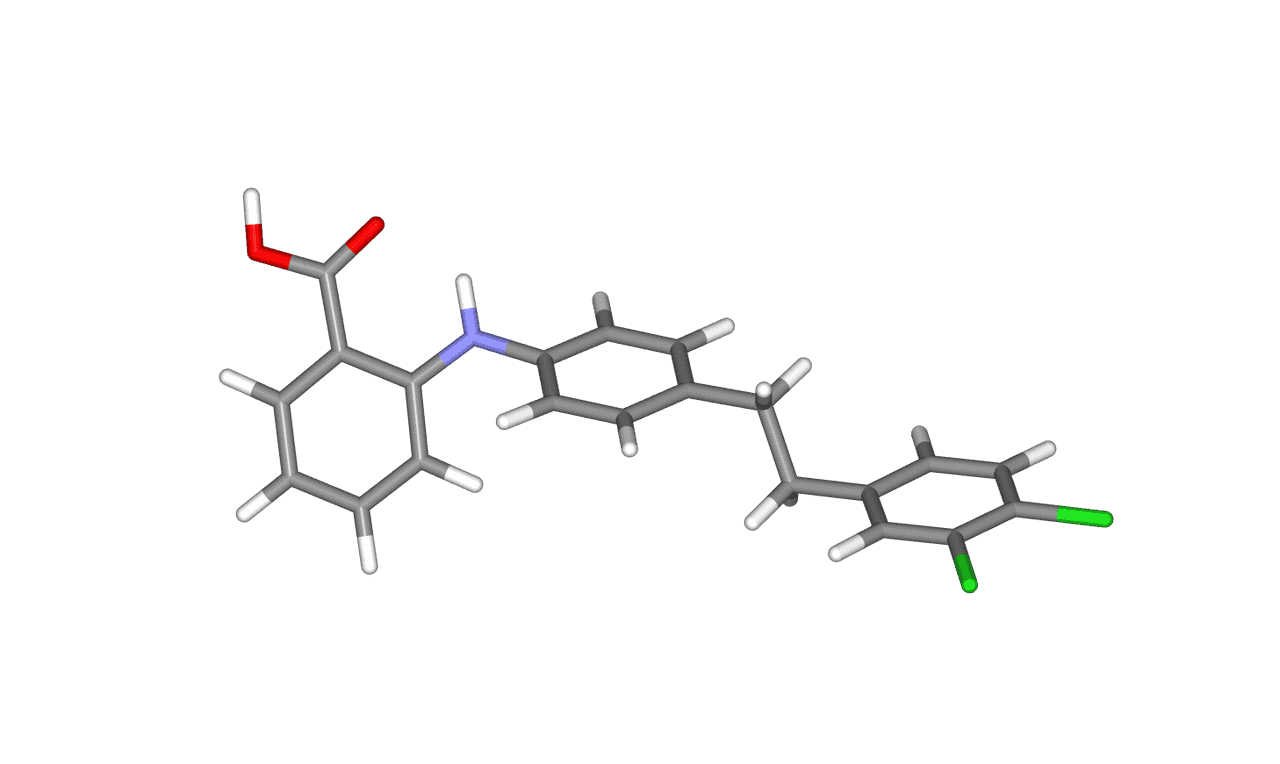

XtalCSP™ Crystal Structure Prediction

CSP driving polymorphic risk assessment & stability analysis

CSP performs the global search of crystal structures of the target molecule and the other optional components in the corresponding searching space, aiming at the crystal structure of the thermodynamically stable crystalline form and the relative stability between stable forms.

Crystal structure prediction (CSP) technology offers a robust tool, bringing computational analysis to the forefront of polymorphic risk assessment. Our CSP services cover a variety of systems including polymorphs, salts, cocrystals, hydrates/solvates, etc.

- Application scenarios

Cross validation between predicted forms and experimental forms to determine the energy ranking of experimentally obtained crystals

Risk assessment of form conversion

Recommendation of experimental conditions to prepare novel crystalline forms

Property predictions (solubility, morphology, mechanical properties, etc.) of crystalline forms in early-stage drug discovery

- Workflow

Input Molecule

Conformation Analysis

Force Field

Training

Training

Crystal Structure Generation

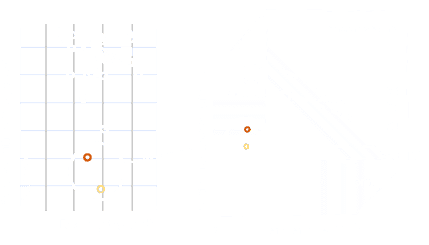

Energy Ranking & Clustering

Energy Landscape & Free Energy Trend

Crystal structure prediction (CSP) performs the global search of crystal structures of the target syste in the corresponding searching space, aiming at the crystal structure of the thermodynamically stable crystalline form and the relative stability between stable forms, to evaluate the polymorphic risk of the target system.

- Technical Advantages

Advantage 01

High availability by State-of-Art technology

Leveraging CSP for broader investigation space, including anhydrates, salts, cocrystals, hydrates and solvents systems with flexible APIs for

Advantage 02

Higher

success rate

Derisked more than 300 systems since 2017 and all crystalline forms obtained by crystallization experiments can be covered in the CSP study.

Advantage 03

Shortened research timeline

CSP can be completed in 2-3 weeks for regular systems and 6-8 weeks for those complex systems

Advantage 04

Reduced

cost

CSP does not require APIs or experimental facilities, which effectively reduces the cost of research and development.

04

Solid-state Virtual Screening Services

Improving solid-state screening efficiency with XtalPi’s virtual platform

XtalPi’s independently developed solid-state virtual screening platform addresses key challenges in the experimental screening process. By computing binding propensities between the target API and various solvents, coformers, counter-ions, and carriers, it streamlines the selection of the optimal coformer.

This reduces the lengthy experimental verification cycles for solid dispersion stability, ultimately improving efficiency and increasing the success rate of solid-state screening.

- Application scenarios

The platform enhances the selection of coformers, counterions, solvents, and carriers for wet-lab cocrystal, salt, solvate, and solid dispersion screening.

- Technical Advantages

Advantage 01

Faster timelines

Shortened project schedules and accelerated pharmaceutical R&D processes.

Advantage 02

Efficient resource use

Decreased sample usage and experiments compared to the shotgun method.

Advantage 03

Enhanced screening

More comprehensive and reliable screening results with less risk of empirical omissions.

05

XtalCSP™ Software Features

Peerless software features and intuitive solutions

Intuitive user interface designed for ease of use for 2D molecular structure

Cloud-based

platform with scalable

resources for faster

turnaround times

Powered by CSP service experiences with more features for comprehensive analysis

Data storage with

robust security and

transfer conform to the

requirement of ISO/IEC

27001:2013

- Technical Advantages

Customizable based on different usage scenarios

User-friendly Ul for non-computational experts

Data can be managed by local Database

Visualizable intermedia and final results

06

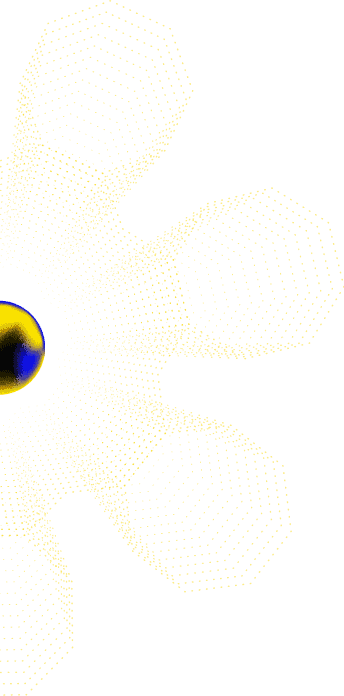

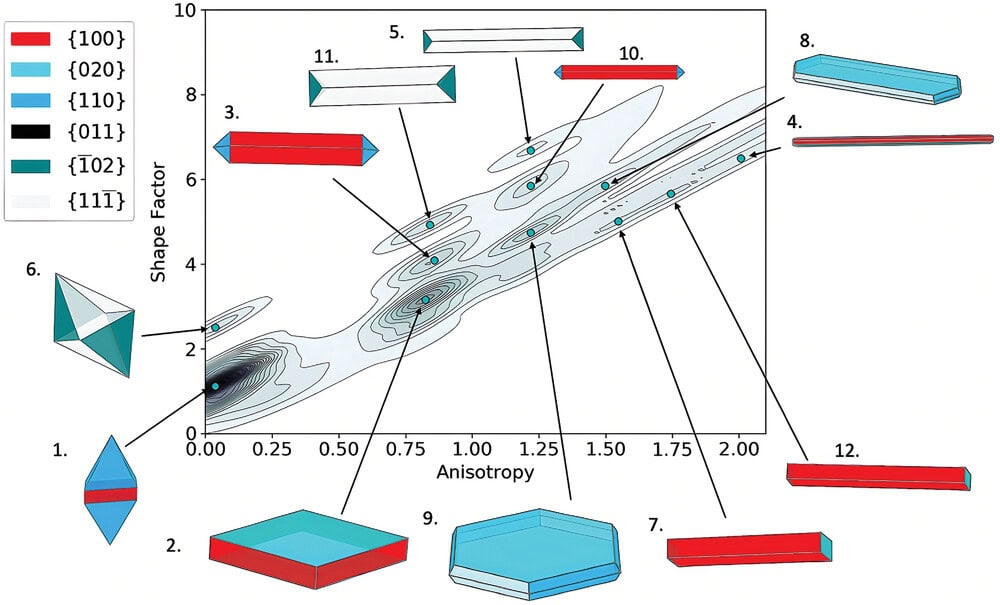

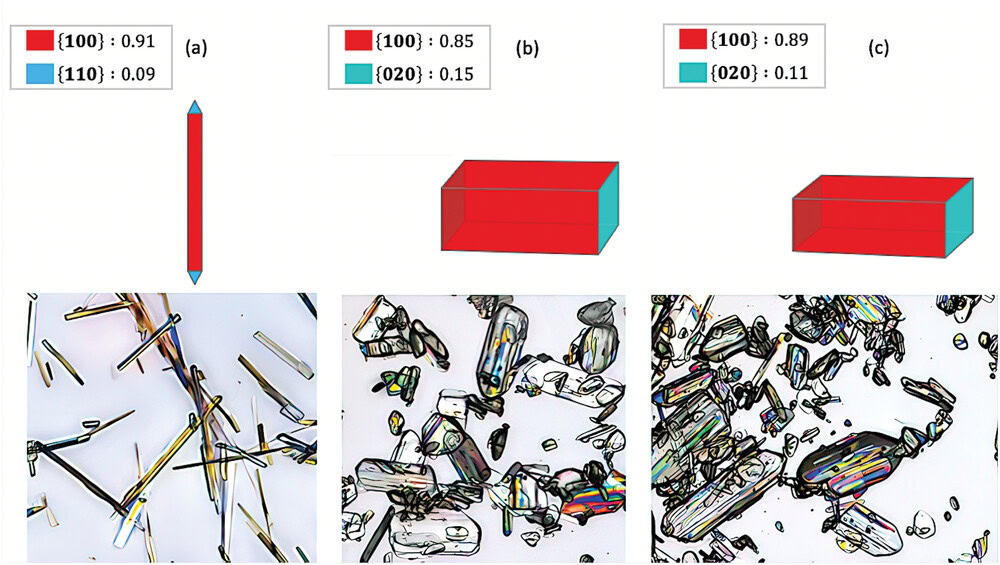

Morphology Prediction

Optimizing crystal morphology with XtalPi’s predictive models

XtalPi leverages multiple models to predict the crystal morphology of a given polymorph under various crystallization conditions. By considering factors like solvent type, supersaturation, and temperature, the platform explores the variability and controllability of crystal morphology.

Adjusting these conditions allows for purposeful changes in the target polymorph’s morphology, streamlining the development of crystallization processes.

- Application scenarios

Crystalline products with preferred morphology can be obtained under recommended crystallization conditions, which facilitates post-processing by avoiding difficulties in filtration or uneven particle size distribution after compression.

Salicylamide in acetone

CrystEngComm, 21,2648 (2019)

EPG in chloroform

China.J. Chem.Eng 15,648 (2007)

- Technical Advantages

Advantage 01

Guided crystallization

Guide crystallization experiments to obtain desired morphology.

Advantage 02

Algorithm accuracy

More robust and accurate algorithms compared to existing software/algorithms.

Ready to streamline your solid state research?

Contact us today, and discover how XtalPi can revolutionize your drug discovery process.